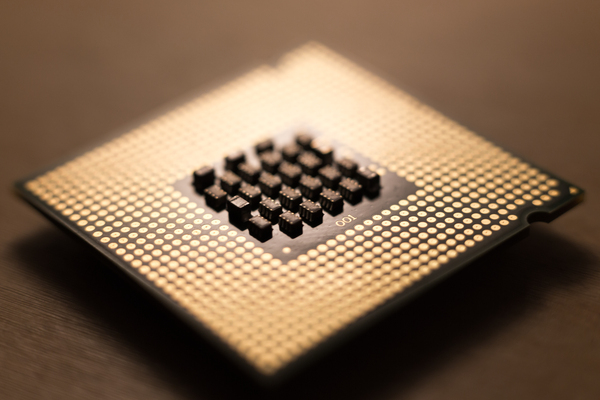

Silicon is everywhere

You are reading this on a device made possible by silicon

Silicon is used in hundreds of thousands of applications, from the solar panels powering our homes to the cars we drive, the cell phones in our pockets, and the medical devices that save lives. Silicon is the invisible force fuelling innovation and progress in every corner of our lives.

Silicon has serious problems

Massive emissions

12 tons of CO2 are emitted for every ton of silicon metal produced, 8x higher than steel.

High production costs

Western producers are shutting down because they cannnot compete with subsidised foreign production.

Extreme supply chain

vulnerability

Nearly 90% of production comes from China.

Kore’s patent-pending Solution

A revolutionary electrochemical process

Radically lower emissions

Kore’s fully electric process slashes emissions by more than 5x, and has the potential to run at net zero.

Superior unit economics

Using low-cost feedstock to produce high-purity silicon metal cost-effectively

Sovereign production

Kore’s process enables production anywhere in the world.

Contact us to learn more

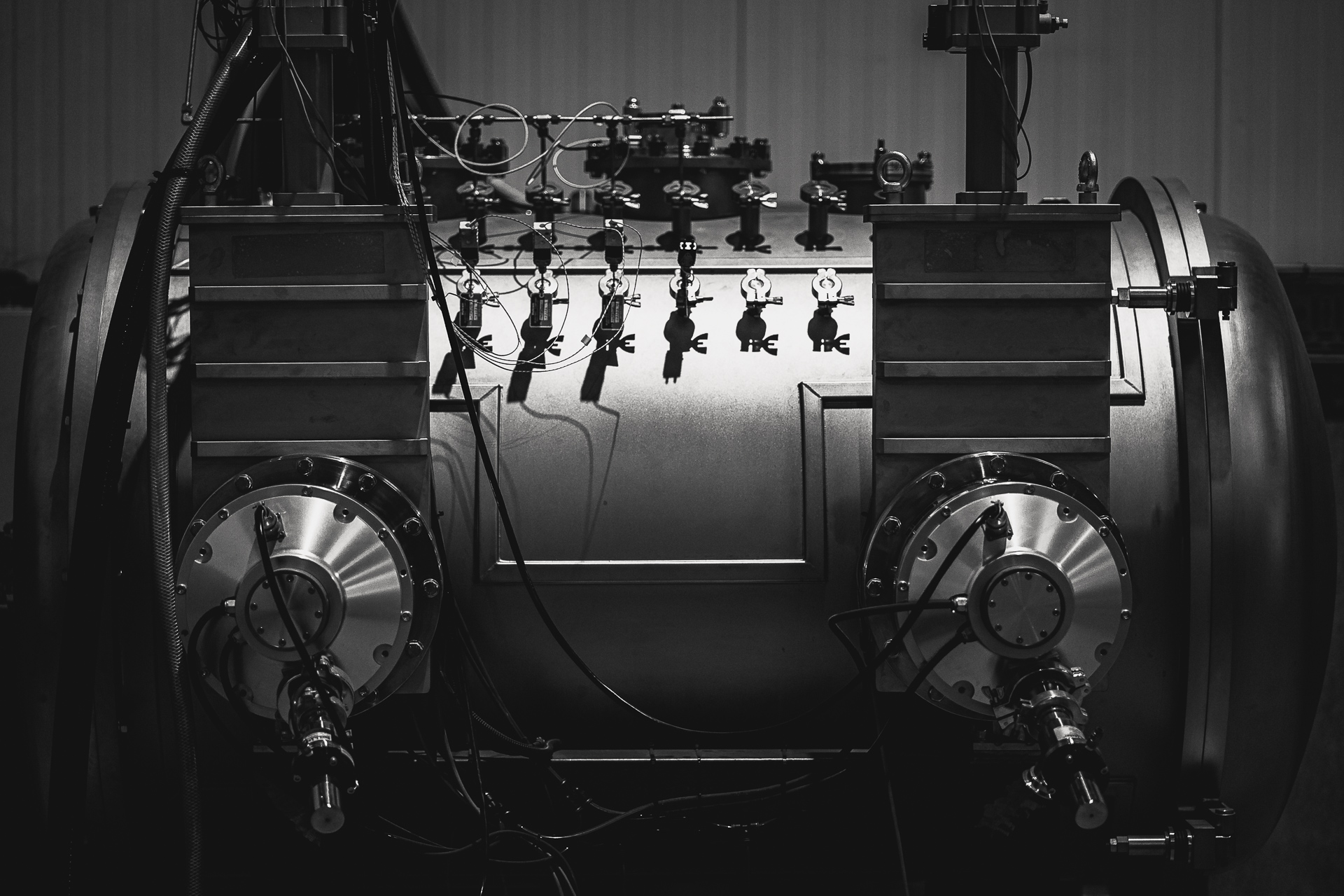

Developed for space, brought back to Earth

Kore’s Molten Salt Electrolysis (MSE) process for sustainable silicon production

Originally developed to produce metals on the Moon and Mars, our patent-pending Molten Salt Electrolysis (MSE) process revolutionizes the way critical and strategic metals are produced. Similar to how aluminium is produced, we use molten salts to dissolve and electrochemically reduce oxygen and silicon.

Our process enables:

1. The use of silica sand as an abundant, low-cost feedstock for producing silicon.

2. Rapid scaling by leveraging existing equipment and know-how from the aluminium industry—90% of the capex of Kore’s process is the same as a primary aluminium smelter.

3. High-value output, producing a product orders of magnitude purer than today’s carbo-thermal methods.

4. Full electrification of silicon production, significantly reducing emissions.